Teddy Bears

The project began as an unusual request for an enormous granite teddy bear. Our client was the head of a large Dallas-based development company, avid art collector, and traveler for whom we had done one other project in the previous year.

In this case our clients' project manager handled all of the details and arrangements for the entire project aside from the sculptural aspects. This was a rather large public art project that involved the client, town council, mayor and Park Advisory Board, residents of the community, as well as landscape architect, general contractor, and an engineering firm. Our client was donating the sculptures to the community.

Our task was to create the focal point of the park. The largest of the group of bears was ten feet tall and weighed nearly twenty tons, but next to a next large body of water and trees, its scale was perfect. This bear needed to maintain a fluffy, friendly, toy-like softness or its size would frighten the children it was meant to please, and it presented an interesting sculptural challenge. Also critical to the overall "feel" of the sculptures was texture. Rough enough to simulate a stuffed toy, but smooth enough to climb on. The features - eyes, nose, and footpads - were all polished for contrast and to reveal the true color of each of the different granites.

Within weeks a form was emerging. Although each of the sections were worked separately, they were proceeding at nearly the same pace and it would be just a matter of time before we could assemble them into a coherent whole, and finish them as one piece.

bronze bowtie

dry-fitting the entire assembly

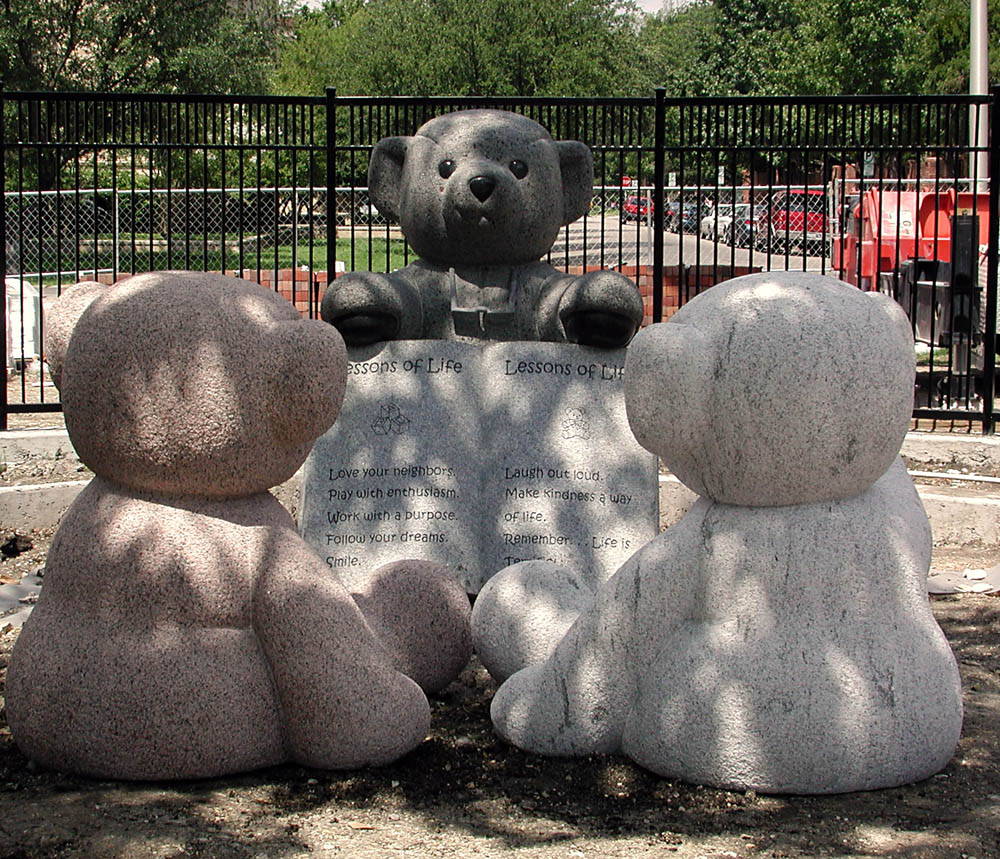

smaller bears

An expert crane operator wove under phone cables, over power lines and between trees in a very confined area. We actually needed to let air out of some times to gain a few inches of clearance. The body sections were up righted and lifted into position with specially designed lift pins that allowed a single-point lift from a hole at the top of each section. The bronze neckband and bow tie were fitted, and pins were inserted and epoxied to the top of each body section to secure the head. A layer of epoxy and a perimeter bead of silicone were applied to the top and we were ready to set the six ton head.

Parents bring their children to be photographed with the bears and the site has become an enjoyable place to visit for the community.

Our clients were well pleased by the quality of the work and the attention to detail throughout the project. We would like to note that our client's project manager did a superb job in keeping the various contractors on track and on schedule, and with the park's crew, made the installation process a smooth and enjoyable experience.

We continue to produce a couple of smaller scale bears in a variety of compositions each year for our clients, which are then generously donated to other sites of their choosing. To date, their population has grown to 13.

Teddy Bears

The project began as an unusual request for an enormous granite teddy bear. Our client was the head of a large Dallas-based development company, avid art collector, and traveler for whom we had done one other project in the previous year.

In this case our clients' project manager handled all of the details and arrangements for the entire project aside from the sculptural aspects. This was a rather large public art project that involved the client, town council, mayor and Park Advisory Board, residents of the community, as well as landscape architect, general contractor, and an engineering firm. Our client was donating the sculptures to the community.

Our task was to create the focal point of the park. The largest of the group of bears was ten feet tall and weighed nearly twenty tons, but next to a next large body of water and trees, its scale was perfect. This bear needed to maintain a fluffy, friendly, toy-like softness or its size would frighten the children it was meant to please, and it presented an interesting sculptural challenge. Also critical to the overall "feel" of the sculptures was texture. Rough enough to simulate a stuffed toy, but smooth enough to climb on. The features - eyes, nose, and footpads - were all polished for contrast and to reveal the true color of each of the different granites.

Within weeks a form was emerging. Although each of the sections were worked separately, they were proceeding at nearly the same pace and it would be just a matter of time before we could assemble them into a coherent whole, and finish them as one piece.

bronze bowtie

dry-fitting the entire assembly

smaller bears

An expert crane operator wove under phone cables, over power lines and between trees in a very confined area. We actually needed to let air out of some times to gain a few inches of clearance. The body sections were up righted and lifted into position with specially designed lift pins that allowed a single-point lift from a hole at the top of each section. The bronze neckband and bow tie were fitted, and pins were inserted and epoxied to the top of each body section to secure the head. A layer of epoxy and a perimeter bead of silicone were applied to the top and we were ready to set the six ton head.

Parents bring their children to be photographed with the bears and the site has become an enjoyable place to visit for the community.

Our clients were well pleased by the quality of the work and the attention to detail throughout the project. We would like to note that our client's project manager did a superb job in keeping the various contractors on track and on schedule, and with the park's crew, made the installation process a smooth and enjoyable experience.

We continue to produce a couple of smaller scale bears in a variety of compositions each year for our clients, which are then generously donated to other sites of their choosing. To date, their population has grown to 13.